|

|

|

|

We developed these TC elements primarily for high power RIMS systems that cannot make use of the traditional ripple shape but will work in tank applications as well. To be clear, these don't have screw in bases but are welded right to a 1.5" TC flange. Not only that, but the electrical connection is made by integrated NEMA L6-30P blades. You can twist an L6-30R cord end right on. This gives you the ability to disconnect at the element rather than drag the cord around.

Element length is approximately 15 " Long to the TC flange. The bundle of four heating tubes is positioned dead center to the TC flange so it will fit down all of our 18" long, 1.5" TC based RIMS tubes without needing any major offset bending. Due to the long length and close tolerance, it may make incidental contact with the RIMS tube but can be tweaked a bit to make space.

Make no mistake about it, the use of a 3500 watt element in a RIMS system is Varsity Level Beer Nerding. With that much power in a small enclosure, you have to make sure wort is flowing and that your temp controller is running a well-tuned PID algorithm with cycle times of less than 2 seconds. We do not replace elements encased in burnt sugar ;-)

These elements will draw just under 15 amps on 240 volts.

Keep in mind that the only controller we sell that can handle 240 volts is the Blichmann Brewcommander

The RIMS equipment is available separately if that is your end application. If you plan to install in your tank/kettle, you will need a 1.5" TC port on your kettle and we offer several different ways to get that done; weld ferrule, solder ferrule, and weldless. These are available separately. The L6 cable is also available as a separate item. Again, this element does not include a gasket, clamp or TC port for your kettle. They are available separately.

Everything is 304 High polish stainless steel.

These are made in China. Warranty is 6 months from date of purchase and does NOT cover damage due to dry firing. These elements must be submerged in liquid any time power is applied.

It is extremely important that you consult with an electrical professional for advice or wiring help. Under no circumstances should these be used without proper wiring, ground fault circuit protection, over current circuit protection. We are not licensed electricians so we cannot provide wiring advice.

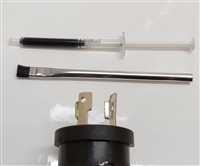

After years of experience with these elements, we have concluded that the connectivity between the L6-30 prongs and the mating female receptacle is a common point of failure as oxidation from humid environments begins to degrade conductivity. The best long term solution we've come up with is the use of a light coating of a product called Conductive Assembly Paste. It is expensive and not usually available in tiny packages but we've done the repackaging locally. We now include a 1mL syringe of this paste with the purchase of this style of element. Note that we only include a single 1mL tube for up to 3 elements purchased.

|

|

|

|

|

|

|