|

The BrewCommander™ complete brewhouse controller is available in electric and gas/propane models! The patent pending BrewCommander™ is a unique, innovative, high-quality brewhouse controller with ultra-high accuracy and precision with the ultimate in flexibility. Whether system-integrated or freestanding, the BrewCommander™ offers automated step mashing, boil timers and amazing advanced settings. Whatever your heating source or brewing setup, the BrewCommander™ offers precision temperature control with increased accuracy and repeatability.

The BrewCommander™ Brewhouse Controller is a high precision, intuitive, complete brewhouse touchscreen controller for automatically ramping and maintaining the temperature of your boil kettle, mash tun, or hot liquor tank. With linear digital power control, automated mash profile ramping, boil addition timers, pump control, delayed starting, and easy to use advanced control settings, the BrewCommander™ is clearly in a league of its own.

This 240v controller is designed to regulate 240v elements up to 7200 watts at 35 amps but a much more common use would be a 5500 watt element on a 30 amp circuit.

Understand the voltage and receptacle/circuit requirements for this unit before purchasing:

|

This is what the L6-30R the controller needs to plug into for touchscreen power and element output |

|

This is what the pump switch circuit is powered by. |

|

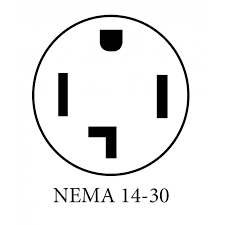

We can install a plug on the controller to power both of the above if you have a compatible receptacle as shown here. See the labor charge options in the accessory list. |

This unit comes from Blichmann with two feed plugs (input power). One is a NEMA L6-30P which is the 240 volt, 30amp input to power the touchscreen and the element output. The other is a common NEMA 5-15P, 120 volt/15 amp plug which only feeds the pump input, switch and pump output. For some folks, this is a perfect configuration because they have a 240v circuit that only has 3 wires (hot, hot, ground). They can find a standard 120v circuit to feed the pump input even if it requires an extension cord.

Note that the male and female input/output plugs are on very short cords (about 10 inches each). The controller also comes with ONE ten-foot long extension cord that you can either use between your wall outlet and the controller or between the controller and your element. If you are using a Blichmann BoilCoil, the cable included with that element will reach the controller on its own. If you are using one of our TC-integrated ripple elements, you may want to pick up an extra extension cord.

TIP! Refer to our controller buyer's guide to compare key features of all the controller's we offer.

Optional Modifications at Brewhardware:

1. Wall Mount Conversion: This unit comes from Blichmann in "table top" configuration as shown in the picture where the cables come through the back plate. It can also be conveniently wall mounted with minor modification. First, you'll need a DIN rail screwed to your wall (we sell DIN rails, see accessory list on the right). Next, you'll open up the box and move all the wires to prepunched holes in the bottom plate. Blichmann does offer instructions on how to do it yourself but if you would rather it just show up ready to wall mount, we offer this reconfiguration service if you would rather not rewire it. This job takes us about 30 minutes and we've done it a bunch of times. It will take you an hour. Use the labor item in the accessories list to the right.

2. 4-wire plug Conversion: As described above the stock unit requires two different outlets. We can combine into a single 14-30P plug if you have a compatible receptacle. We also install an inline fuse holder and fuse inside the unit to protect the pump circuit and controller. Use the accessory on the right.

3. BOTH: Wall Mount AND 4-wire conversion - Add BOTH labor items to the cart.

Understanding the "relay module" add on unit:

There seems to be a little confusion on how the add on relay module can be used to expand function to multiple elements. The relay module simple allows an additional circuit/element to be regulated by the same controller. That second element is being turned on and off at the same time as the circuit/element on the primary controller module. In other words, it is not for controlling elements on separate temperatures. The primary application for the relay module is to controller two elements in the same vessel when the size of that vessel can no longer be heated by a single element.

Can the relay module be used to switch the output between elements in two different pots like an HLT and BK? Sort of. With some clever wiring and the addition of a selector switch in the face of the relay module, you COULD use a single unit to switch between two elements. The only downside is that you will not have temperature probe feedback from the boil kettle. In general that's not really a problem as the controller will operate fine during the boil mode without knowing the boiler's temperature. The work-around to this is purchasing an extra temperature probe and install bulkhead so you can leave a probe installed in both your HLT and BK.

Key Features:

- Intuitive Touchscreen Interface.

- Keypad Data Entry.

- Advanced Temperature Control Algorithm.

- Automated Step Mashing (up to 5 steps and 9 profiles).

- Boil Addition Timers (up to 7 additions and 9 profiles).

- Integral Pump Switch.

- Lab Grade Precision Thermometer - Superior to RTD's.

- Customizable Settings - Basic and Advanced.

- Mash Step Ramp Rate Delay.

- HERMS / RIMS Offsets.

- Audible Alarms.

- Upgradable Firmware.

- Switchable Between Table and Wall Mounting.

- Modular - Connect Multiple Units!

- Optional SparkBox™ Remote Ignition Module.

- Offered in Electric or Gas Versions.

Probe Accessories Explained

|

|

|

Blichmann Brew Commander Controller - 240V

Blichmann Brew Commander Controller - 240V